Waste leachate treatment project in Laixi

Zero discharge of sewage treatment

Zero discharge of wastewater means to recycle all(more than 99%) the wastewater which contains high quantity salt and pollutant after the water is used repeatly or filter out water-insoluble substances from the water for recycle.No waste liquid is discharged from the factory. The salt and pollutants in the wastewater will be sent to the waste disposal plant in solid form or taken as useful chemical raw materials after being concentrated and crystallized.

The zero-discharge technology is a combination of physical and chemical processes such as membrane separation, evaporation crystallization and drying. The solid impurities in the wastewater are concentrated to a very high concentration. Most of the water has been recycled, leaving a small amount of water containing solid waste. Each enterprise can chooses from the following treatment process according to their conditons to treat the water with high content of solid waste instead of discharging out of the system (the following three factors should be considered when choosing this “zero discharge” : environmental protection requirements – economic costs (enterprise competitiveness) – production safety).

Zero discharge applicable industries: mine water treatment, power plant wastewater treatment, smelting wastewater treatment, RO concentrated water treatment, and water reuse projects.

1)Zero Discharge Process

The evaporation crystallization technology concentrates the wastewater by a series of methods, and the concentrated liquid will be evaporated and crystallized again, and the steam is recovered by condensation, and the salt crystals are dried to form an industrial salt, thereby achieving the purpose of zero discharge of the wastewater. At present, there are two main types of wastewater evaporation crystallization technology:

a)Multi-effect evaporation technology

The multi-effect evaporator salt making method is a method of removing the inorganic salt in the waste liquid by evaporation with an evaporation concentration crystallization system.

The multi-effect evaporator is composed of a plurality of evaporators connected in series with each other, the saturated heating steam is introduced into the first effect, the waste liquid is heated therein, and the generated steam is introduced into the second effect as the heating steam, so that the second-effect waste liquid is evaporated at a lower temperature than the first effect, this process is repeated until the end effect. The first effect condensed water is returned to the heat source, and the other condensed waters are collected as fresh water and discharged.One part steam is supplied to evaporate a plurality of times of water. At the same time, the high-salt wastewater is concentrated from the first effect to the final effect, and the crystallization is precipitated at the end effect, thereby realizing the solid-liquid separation of the salt.

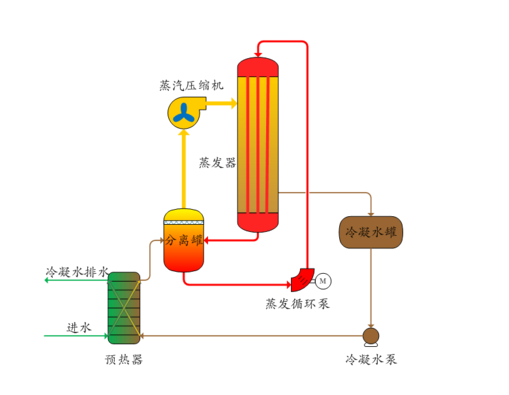

b)MVR evaporation technology

The so-called mechanical vapor recompression cycle evaporation technology is based on the principle of physics. The same amount of material needs to absorb a certain amount of thermal energy during the process from liquid to gas. When the substance is changed from a gaseous state to a liquid state, an equal amount of heat energy is released.

According to this principle, when the wastewater is treated with such an evaporator, the heat energy required to evaporate the wastewater is supplied by the steam condensation and the release of heat energy when the condensed water is cooled. In the course of operation, there is no loss of latent heat. What is consumed in the operation is only the electricity consumed by the pumps, steam pumps and control systems that drive the wastewater, steam, and condensate circulation and flow in the evaporator. In order to resist the corrosion of the wastewater to the evaporator and guarantee the life of the equipment,the main body of the evaporator and the internal heat exchange tubes are usually made of high-grade titanium alloy.

2)Zero Discharge project process

Process1: Industrial wastewater—Ultrafiltration—RO—high pressure RO—Evaporation crystallization(mixed salt)

Process2: Industrial wastewater—RO—Nanofiltration—Electrodialysis—Evaporation crystallization(Sodium chloride salt)

|

High Pressure RO—Evaporation crystallization(Sodium sulfate)

Process3: Industrial wastewater—Ultrafiltration—RO—(High Pressure RO)—1#MVR evaporator system—2#MVR evaporator system

| |

Sodium sulfate Sodium chloride salt

3)Zero Discharge Project

|

No |

Item |

Introduction |

||

|

1 |

Name |

Waste leachate treatment project in Laixi |

||

|

2 |

Address |

Shandong Qingdao |

||

|

3 |

Treatment of wastewater industry |

Dangerous waste leachate wastewater |

||

|

4 |

Capacity |

1t/hMVR evaporator, 3t/hMVR evaporator, 4t/hMVR evaporator |

||

|

5 |

Process Technology |

Landfill Leachate - Biochemical Treatment - Reverse Osmosis - High Pressure Reverse Osmosis Treatment - Preheating System - MVR Evaporation Concentration - Mother Liquid Drying Treatment |

||

|

|

Raw Water |

Raw water index: raw water PH: 8.82; density 1.002g/ml; COD: 1520mg/L; salinity: 10.6%; conductivity: 9.88ms/cm; TDS: 4.93g / L; chloride ion: 2.1g / L; hardness : 360mg / L (calculated as calcium ion); The raw water has high hardness, and the raw water is softened and then evaporated. The evaporation temperature is about 92-95 °C. During the evaporation process,a lot of foam occur and the defoaming treatment is needed which will make sure good evaporation effect.The organic matter in the mother liquor is enriched in the later stage, resulting in higher evaporation boiling point. The mother liquor will be dryed after discharged from the evaporator. |

||

|

6 |

Process introduction |

First to reduce the COD of the waste leachate by biochemically treatment.After the RO reverse osmosis and the DTRO membrane concentration,the outlet water will meet discharge standard.The reverse osmosis concentrated water is finally treated by evaporation. The evaporating condensate water is dischaeged after it is cooled and treated by RO filter. |

||

|

7 |

Project Photo |

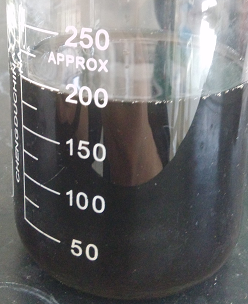

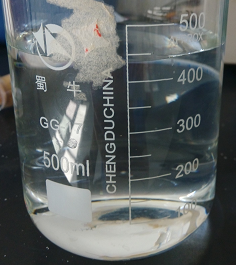

Inlet water |

Evaporate water |

Mother liquor after evaporation |

|

|

||||